Boat School Launches 3 New Student-Built Boats

A Marsh Cat, carbon fiber dinghy, and Culler sailing skiff all hit the water.

n Friday July 21st students at the Northwest School of Wooden Boatbuilding launched multiple student-built boats demonstrating a variety of construction techniques they have learned. The Marsh Cat is a 15’ cat boat designed by Joel White that includes both composite and live wood construction. Boatbuilding Instructor Bruce Blatchley guided students through a broad range of techniques including strip plank and cold-molded construction, curvy and complicated laminated bench supports, lightweight and hollow spruce spars, fine joinery, and finnicky steam bent coamings. He notes “the boat’s fair lines, a hull that feels smooth as you run a hand over it, and an impressive contrast of stark white paint against the warm contrast of sapele hardwood all tell you this boat was crafted by hand.”

Students also launched a 10.5’ carbon fiber dinghy, surprisingly lightweight at only 70 lbs. Guided by Boatbuilding Instructor Korey Ruben, the students employed traditional techniques to meticulously fit and shape the foam core and carbon fiber into the dinghy mold. Throughout the process, they focused on various aspects of composite construction, with a particular emphasis on infusion methods. These methods necessitate precise sealing of the vacuum bag, connecting vacuum lines, and handling resin flow. The project got a boost from Cape George Marine Works who lent the mold for the students’ use. During the launch, Instructor Korey Ruben emphasized that the boat featured some wood components in the form of locust cleats. He also expressed, “It was great experience for the students to witness the entire process and be involved in the complete spectrum of the build – from prepping the mold, infusing the part, doing the finish work, to finally launching it.”

Students enter the Boat School with a wide variety of backgrounds and skills, and many are changing careers — coming from jobs in tech, food service, military, healthcare, and beyond — drawn to working with their hands. Students learn on a wide range of boat projects ranging from 8 to 36 feet, constructed through carvel, lapstrake, and composite construction techniques on power, sail, and row boats. Graduates go on to employment in boat shops, shipyards, fine home construction, educational institutions, cabinet shops, and in related woodworking trades, such as furniture-making, architectural woodworking, and musical instrument making.

Two of the boats launched on Friday have places to sail and row home to. The Marsh Cat is set to be a warmly welcomed to the city of Kennewick on the Columbia River, while the carbon fiber dinghy will act as a tender to the 109-year-old 36’ raised deck cruiser GloryBe.

Betsy Davis, Executive Director joined students on the water. She observed with a smile “there’s not a better time of year to splash new student-built boats than summer in the Pacific Northwest.”

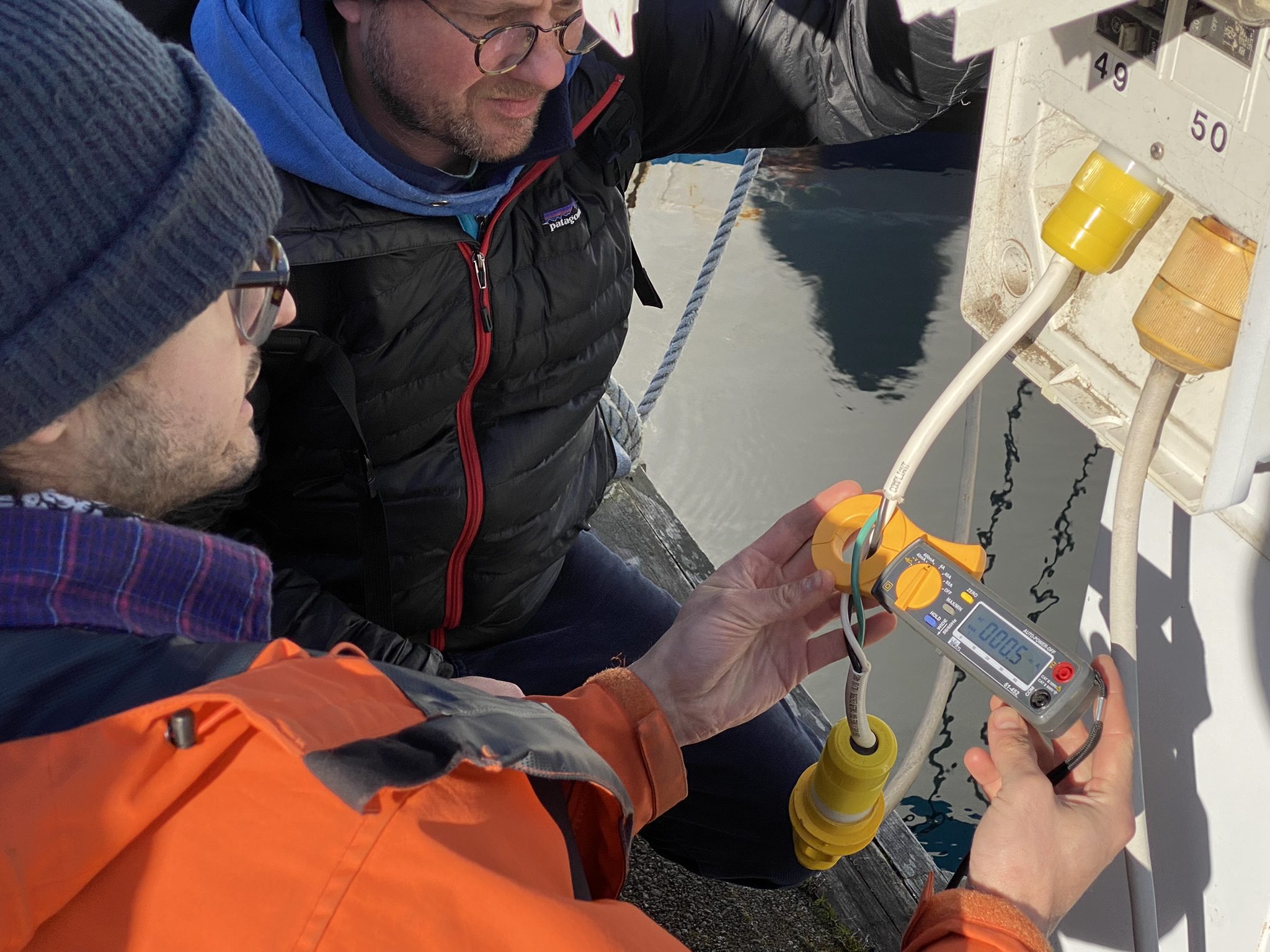

Frayed wires, lack of proper electrical grounding and poor maintenance by boat owners can lead to electrification of marina water surrounding docks and boats. Even a small amount of electrical current can cause paralysis and death to swimmers in the vicinity of the leaking electricity. While electrical shock drowning is more commonly associated with fresh water marinas, salt water can still be very dangerous if electrified.

In a random sampling of fresh water marinas in the US, approximately 13% of the boats tested were leaking potentially lethal amounts of electrical current. Leaking current is also responsible for greater consumption, higher energy bills and promotion of corrosion of metals in boats and docks.

Updates to electrical codes are being instituted to protect from stray electrical current at marinas and it’s recommended that electricians certified by the American Boat and Yacht Council (ABYC) complete yearly inspections and installation of equipment to protect from electrocution. 90% of Marine Systems graduates from the Boat School will receive ABYC Electrical Certification, making them qualified to detect and repair leaking electrical problems in boats and marinas.

Eron Berg, Port of Port Townsend Executive Director described the recent effort as a great collaboration. “We really appreciated the Boat School staff and students working with the PUD to help the Port understand what’s happening electrically in our marinas. Stray current is a big deal and the findings of this effort will help us improve conditions at both Boat Haven and Point Hudson.”