The Northwest School of Wooden Boatbuilding has completed construction on a 25′ zero-emission pump out boat which will provide free services in Port Ludlow Bay. This pilot project features electric and solar technology and a corrosion prevention system which will keep heavy metals out of the water.

The project came together through a collaboration with local marine businesses, private donors, and state agencies aligned around a common goal of promoting environmental stewardship – from its zero emission propulsion system to its role in keeping waterways clean of wastewater. Clean Bay has already been recognized by the state’s

Maritime Blue Initiative for modeling effective use of zero-emissions systems for workboats.

“Building Clean Bay has given students experience with laminating, strip-planking, and cold-molded construction; vacuum infusion; foam core construction; working with CNC production; millwork; and joinery, says Contemporary Boatbuilding Instructor Bruce Blatchley. Students in the Marine Systems program received valuable experience with custom systems design and installation, load calculations for propulsion and energy storage, sizing of solar modules, and impressed current cathodic protection. “Working closely with designers and composite specialists in town gives our students firsthand knowledge of new technologies,” says Bruce.

Construction of the workboat was completed mid July and handed off to the Marine Systems students, who completed their work at the end of August 2021. Clean Bay was launched on August 31st and following sea trials made way her down to Port Ludlow. Chris Mullin, the school’s Prothero intern, is completing the finishing touches.

Community Focused

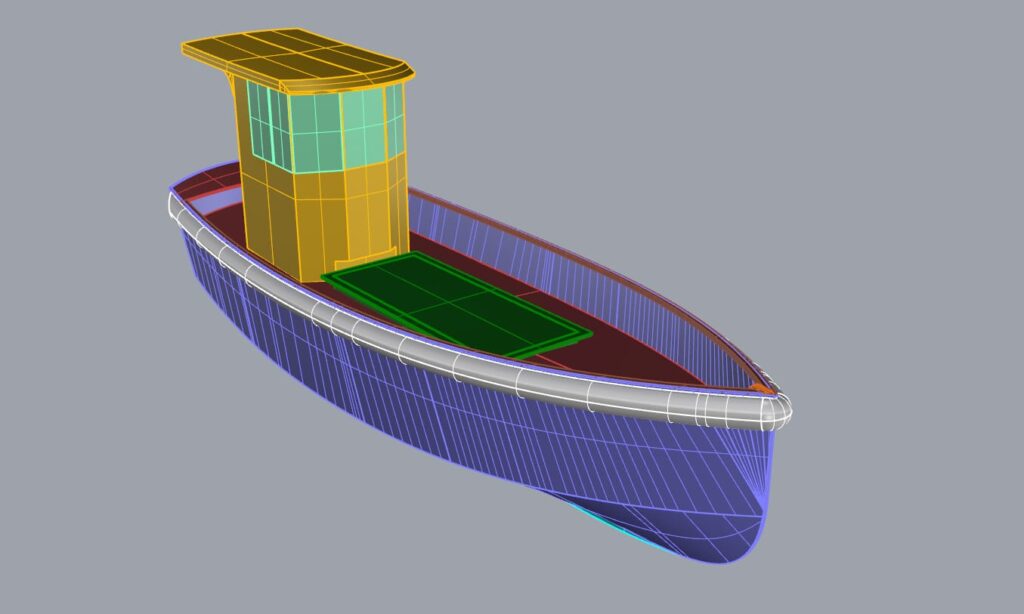

Locally Designed. Naval architect Tim Nolan, based in Port Townsend, WA, developed the CLEAN BAY design.

Locally Engineered. Turnpoint Design, based in Port Townsend, WA, used CNC technology to cut the CLEAN BAY forms.

Locally Built. Students at the Boat School, based in Port Hadlock, WA, are building the hull, deck, house, and installing the marine systems.

Locally Operated. Port Ludlow Marine will operate the CLEAN BAY pump out boat, offering pump out services to any vessel in Port Ludlow, WA.

The CLEAN BAY design by Tim Nolan

Frames cut by Turnpoint Design

Designed to Teach

The CLEAN BAY pump out boat was a perfect platform of learning for students to learn hands-on skills such as:

- Laminating, strip planking, and cold molding techniques and construction methods

- Vacuum infusion

- Foam core construction

- Working with CNC production

- Millwork and joinery

- Custom systems design and installation

- Load calculations for propulsion and energy storae

- Sizing of solar modules

- Impressed current cathodic protection

A student works alongside instructor Bruce Blatchley on the CLEAN BAY.

The CLEAN BAY under construction in the Contemporary Boatbuilding program.

Environmental Stewardship

The CLEAN BAY pump out will has carried environmental message through its design and construction, as well as, its future intended function. It was constructed and will be operated using sustainable technology. We know that:

- Free pump out opportunities will increase use of the service

- Research by Washington Sea Grant shows boat owners are more likely to use portable pump out boats than stationary facilities

- This proof-of-concept electric and solar work boat will: reduce carbon its footprint, reduce vessel noise which impacts local whale populations, reduce potential for small oil and fuel spills, reduce the release of cadmium and other metals associated with some corrosion protection systems.

October/November 2019 Professional Boatbuilder Magazine